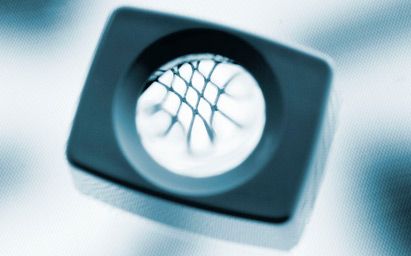

Expanded metals and polymers are produced on expanding lines designed to meet strict product specifications. The mesh is available from most metals, alloys and polymers. The number of openings as well as corresponding open areas are infinitely variable.

- Single unit material structure

- Anti-ravel

- Multiple opening profiles

- Flexible

- Easily formed

Precision expanded materials are available in 3-D and 2-D profiles, provide improved strength and weight reduction, and may reduce costs.

- Medical

- Lightning Strike Protection

- Batteries.

- Composites

- Renewable Energy

- Shielding

MicroMesh is available in Aluminum, Copper, Inconel, Nickel, Titanium, Stainless Steel, Zinc and most any ductile alloy.

- ECTFE

- Nylon

- Polyethylene

- PTFE

- PCV

- PEEK

- PET

PolyMesh can also be found in food service use, medical devices and wherever other precision polymer mesh materials are required.

Micromesh is precision expanded mesh manufactured to specific weight and dimensional requirements. All materials are quality and process assured to ISO 9001 or AS9100. We manufacture from .001″ or (25µm) thick, up to 48” (1250mm) in width in either sheets or coil from most any commercially available or proprietary ductile material or alloy.

Micromesh expanded metal is used in a variety of applications. The common uses for micromesh include:

- Lightning strike protection for composite structures

- Batteries

- Fuel cells

- EMI/RFI shielding

- Filtration

- Acoustics

- Audio speaker grilles

- Facades

- Heating

- Medical

- Retail store displays

- Water treatment

- Ventilation/HVAC

- Wherever specialized mechanical, electrical and precision characteristics are required.

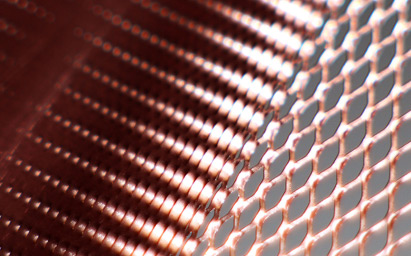

Micromesh can be manufactured from most any commercially available or proprietary ductile material or alloy. We frequently produce a variety of base metals and alloys including stainless steel, titanium, aluminum, silver, copper, brass, nickel, mild steel, and zinc.

Micromesh precision expanded metals are available from .001″ or 25µm (microns) thick, up to 48” (1250mm) in width in either sheets or coil lengths. Micromesh is available in a variety of both 2D and 3D designs including diamond, square, sound and hexagonal patterns. All patterns can be modified through specialized manufacturing methods to increase or decrease the open area. In addition, Micromesh can be further customized to include solid or ribbon sections incorporated into the sheet to enhance the material’s appearance. The one-piece construction of Micromesh expanded metals creates strands and bonds of the mesh shapes that add strength and rigidity to the product which won’t ravel under normal circumstances.

Micromesh provides significantly greater conductivity than woven mesh when used for lightning strike protection, reduces the volume of unwanted frequency levels when used for EMI/RFI shielding, provides excellent sound absorption when used for acoustic applications, and offers the best combination of sound transparency and visual concealment when used for audio speaker grilles.

The wide variety of finishing options available for our precision expanded metals provides our customers with solutions to best meet their needs. Micromesh products are available in multiple base metals and alloys including brass, copper, nickel, titanium, zinc, mild steel, silver, aluminum and stainless steel. Micromesh products can be finished using anodization, e-coating, painting, powder coating, anodized, e-coated, painted, powder-coated, or composite finishing options.